Back from the Brink!

The following story comes from Nottingham, and Andrew Blagg who comes from a long line of Farming families and Contractors.

Andrew has always been fascinated by combines and harvesting, and has been involved from a young age on his family's farming business, his family ran several Allis Chalmers combines when he was young and his neighbours used MF 780s, Andrew spent many hours on his neighbours Masseys, and quickly learnt about all aspects of operating these popular combines.

Undertaking any type of restoration on any vehicle requires a lot of commitment and a good sense of humour to help you through the dark days when everything seems to be going wrong!

Normally with a tractor the first step would be to assess the condition of the engine! And that might mean putting it to work on a plough or something heavy to gauge the performance and power output of engine any smoking of exhaust ,sump pressure breather, oil pressure, water temperature, clutch and gearbox etc

.The biggest problems with combines is despite all the very best inspections the real test comes when it is put into crop and under load! And it's not always possible to carry this out.

With a combine the list is endless! Engine, belts, chains ,bearings, pulleys, shafts, augers, straw walkers, shaker shoe, sieves, gearboxes, hydraulics, etc.. the list is endless then you assess the bodywork, guards, and structure of combine, any serious rust and rot is very costly and time consuming to rectify, these machines don't fair well left out to the elements, they have so many water traps throughout the structure that within a very short time rust will take hold and render the machine suitable for scrap only! I have personally seen so many abandoned in the open by owners who probably had intended to find storage but other pressing storage issues prevented this.

Another major problem is parts spares etc.. even well known combine breakers would unlikely now carry second-hand parts for a 60 yr old combine!

So you're last resort would be to find someone with an old machine abandoned on their farm and hope you can persuade them to let you strip off parts for a financial remuneration! Although this isn't always so straight forward! As some owners are not that obliging unfortunately.

If possible a second machine bought for spares would be a huge advantage for the restoration and future successful operation of the combine.

Andrew was fortunate to of purchased two combines using one for his spares from the same owner in Cornwall, this model is a 1958 780 special the updated version of the 1953 designed 780.

The combine designed in Canada was badged the MH21, the 7 denotes it was built in Kilmarnock as was their build code.

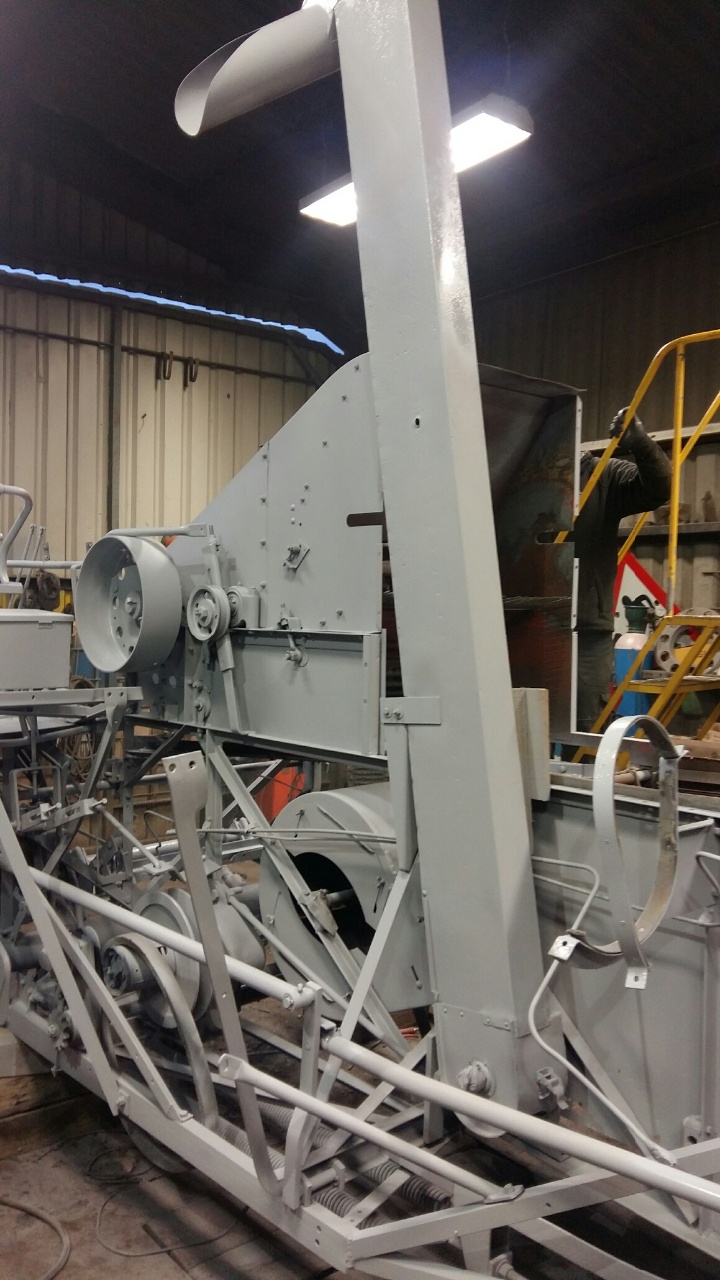

Strip down continues, many many hours will be required to carry out a full rebuild of this combine and it can quite easily look very daunting at times, the fanning mill at bottom of picture would need to be completely rebuilt, these are always favourite to rust out when combine is left outside as they hold water like a bucket even though they are underneath combine.

Andrew has over the last few winter months, snatched any spare time he has to devote it to the combine restoration, but this isn't easy as his working life today sees him Running his successful road planing operation which is countrywide.

But Andrew makes use of the precious time available and large workshop and tools on hand to help him strip and rebuild this old lady in red.

One big problem Andrew had to contend with was a large bee's nest inside the centre of the table auger, this nest had been there for a long time and the centre of the auger was packed with honeycombe! This problem meant a delayed start for the work as no one fancied tackling the thousands of bees that were housed in the auger.

After acquiring some professional help to remove bee's the table was removed and work started here first replacing the table bottom that was wafer thin with a new skin and the reel received New battons, the auger finger cam also required work to take out wear around the finger holders.

The original L4 engine was seized solid, and faced a total restoration, but Andrew had a D270 that came from a 788 Massey combine, this engine ran ok and would require less work so he preferred to put this engine back in his combine.

Andrew has made full use of his donor 780, he has retained many good second-hand belts and a few pulleys that had less wear on, also drive chains, the only new parts at this stage is a couple of new rear tyres that will be fitted on completion.

The front tyres came from the donor combine which were in better condition, so this machine can be kept in as original condition as possible.

The rear beater on combine was subject to a total rebuild, as was the grain pan that was badly corroded, the auger housings still retained a good thickness of metal, however New rubbers were fitted to the elevators which was a tedious and time consuming job.

Andrew already has a very tidy French built Massey 892 combine, this model was built in France and was in its day the largest combine available by Massey.from 1958/ 1964

The rear hood section was subject to a lot of attention a few plates were welded into some very badly corroded areas and some of the strengthening slats had to be replaced, but the good thing was that the hood could be laid flat on the floor and was easier to work on and turn over to gain better access to all areas.

Obviously all the nuts and fixing bolts would have to be replaced as they were cut off due to corrosion, and there are a lot of them to replace! For sure!.

The first self propelled Massey Combines in Europe were first assembled from kit form in Manchester by Massey Harris in 1947, and just a year later full production moved to their factory in Kilmarnock Scotland.

By 1953 the 780 was launched onto the market by now which was hungry for bigger machines, in this decade after the war the European nation was still reeling from the effects of the war, and the farming communities had the formidable task of feeding a rapidly growing nation, which would require output at harvest time that had never been seen before.

Of all the combine models produced the 780 will be remembered by many as the combine that changed harvesting from the Labour intensive chore that it was into a one part operation, and for sure the farming landscape during summer would never be quite the same again.

One of the best quotes I heard from these early days came not from a farmworker! But a commercial traveller, he wrote in his diary, "As I travel across this late summer East Anglian countryside it seems this golden fabric of landscape is crawling with red ants in twos threes and even more moving across the land devouring everything in their path"

It would certainly seem this way in the late fifties with large estates running many machines some in the same area, and by this time many owners had converted their previous bagger combines to tanker models to which Massey had set up a do it yourself tanker kit conversions! available from local dealerships.

Within a few short years of the launch of the 780 many owners had complained the combines were struggling with the higher yielding crops which had been developed just as fast as the new technologies in harvesting.

And not to forget this combine technology had its roots in America where crops were much lighter and also drier, Massey engineers increased the size of the separation area by lengthening the combine, and as the yields were by now 1.5 /2 ton per acre this for now would suffice! But as crop yields were increasing they would have to push for even bigger output machines ,and this was exactly what would happen in the following years.

More on Andrews 780 restoration in 780 pt 2

Frances Green

Hello- I work for a documentary production company called Windfall Films and we would love to have a chat with you about the restoration of the combine harvester.

Colin Cloude

Hi Frances

My email address cloudejake@aol.com

Regards Colin

Garry healey

Hello There. Have you ever come across a KB double pulley for a 780. Regards Garry.

DAN

Hi 788 well under way will the air duct off and all the bearings being replaced inc new traction belt coming any idea what the correct yellow and red colour is please?

Drew Bingham

Fantastic to see someone restoring the Massey Harris Ferguson Heritage My father started with a 780 moved up to an 80 rice special then a super 92 both of which are in storage waiting restoration

Colin Cloude

Hi Dan

We use Massey old Red paint! Not the super Red! That came out much later! The original Massey early yellow was similar to Cat colour ! But we only use Matbro yellow on our combines! For wheels

Theo

Hi, I currently have a 788 sat on farm, good running order and driven regularly. Was wondering if anyone interested in purchase

Thanks

Colin Cloude

Hi Theo could you email me some photos please? And whereabouts Combine is situated please?

Regardscolin www.cloudejake@aol.com

Dan

Hi presently brought a 788 10ft ! Wondered if u know if the ignition key is a Lucas as previous owner died and his son can't find the key. Any help would be great.

Chris

Hi there. We have a 788 in good condition that has been kept in the dry down in Devon . Would there be any interest in it do you think for parts or restoration?

Colin Cloude

Hi Chris

Thank you for contacting yellowswirl. Could you send me photos please?

Regards colin cloudejake@aol.com

Steven mair

I’m in the process of buying a tidy 780 it has the horizontal air intake, so would that make it a 780 special, did the 780 special’s have diesel engines

Colin cloude

Hi Steven it sounds like you have a 788? There! Can you send in any photos and give me the serial number!? Regards colin

Richard Burnham

Nice one Andy i hope it all works well. Done a good job welding that straw hood. funny you had a bees nest i had a wasp nest in my gleaner auger before harvest. I will pop round for that cofee in a couple of weeks and i have a look at the 780.

Colin cloude

Steven thank you for your comments! Hope you find a combine! They turn up now and then, in various conditions, good luck with your search, keep in touch. Regards Colin

steven Mair

Great article, I hope to own a 780 special or 788 myself someday. Recently I stumbled across a really tidy MF 892 , I will try and upload some pics.